NEWS

Sheet Metal Fabrication Technology And Applications

1. What is sheet metal?

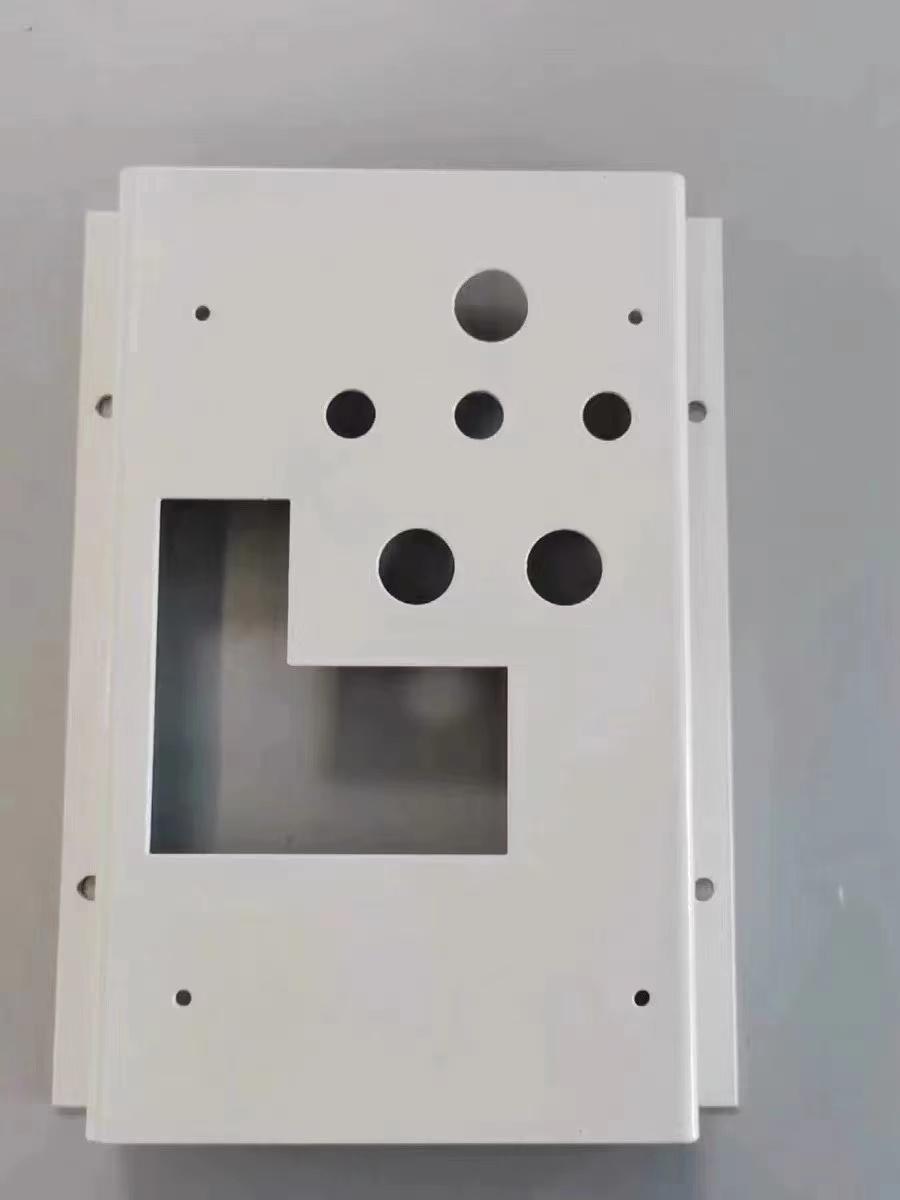

Sheet metal parts are parts made by a comprehensive cold processing process for metal sheets (thickness is usually less than 6mm), including shearing, punching/cutting/compositing, folding, welding, riveting, splicing, forming and other processes.

2. Processing process

1) Cutting (laser cutting)

Laser cutting is a common cutting method in sheet metal processing. Laser cutting metal stainless steel and other plates according to the size specifications of the finished sheet metal parts to achieve the required size for backup. The maximum cutting thickness can reach 35mm, and the effective processing range can reach 6000*2000*350.

2) Bending

The bending process is to CNC bend the finished materials according to the size specifications of the sheet metal processing parts. Generally, the bending thickness can reach 10mm, the bending length can reach 3000mm, and the bending accuracy is within the range of ±0.2mm.

3) Welding

Welding of sheet metal parts is divided into two methods: manual welding and robot automatic welding. The welding groove form and size are mainly welded according to the regulations of GB/T985.1 and GB/T985.2. In this way, the welding process will be more efficient and the welding completion accuracy will be higher.

4) Surface treatment (polishing)

There are many types of surface treatment techniques for sheet metal parts. The more common specific processing techniques include hot dip galvanizing, cold dip galvanizing, galvanizing coloring, powder coating, sandblasting, anodizing coloring, blackening, polishing and brushing. etc. At the same time, the quality of surface treatment will directly affect the appearance smoothness and precision tolerance of sheet metal parts.

5) Baking paint

The main purpose of baking paint is to put a "vest" on the sheet metal parts. The sheet metal parts can be put into different new clothes according to their different uses. Of course, they can also be sprayed in different colors according to the customers' individual needs. There are many factors that need to be considered in the main process of the baking process, such as temperature, time, paint color mixing, etc., which all need to be confirmed in advance.

3. Application industry

Sheet metal products are also used in a wide range of industries, such as the 3C semiconductor industry, lithium battery industry, new energy vehicle industry, medical industry, etc., which all use sheet metal products.

RELATED NEWS

- What does CNC mean? 2023-08-14

- Benefits of Metal 3D Printing 2024-01-14

CATEGORIES

CONTACT US

Contact: Artcoway

Phone: +86 13827407122

E-mail: sally@artcowaymodel.com

Add: Baoan District, Shenzhen, Guangdong, China

Artcoway

Artcoway